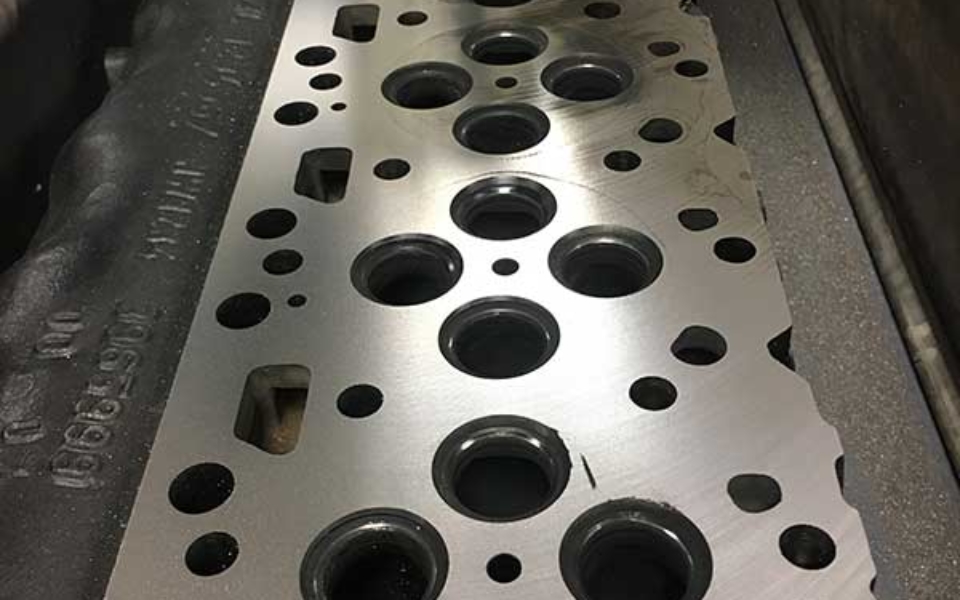

Custom Performance Gas & Diesel Engine Building

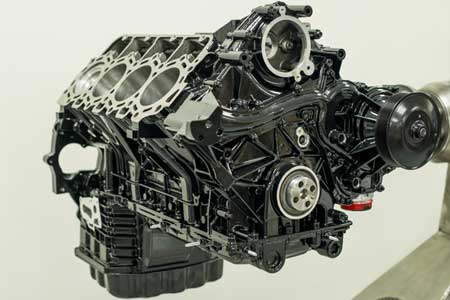

Our process and attention to details has no limits, especially in our custom engine facility. Whether we are installing an engine we built, or we are shipping it across the country to you to install in your garage, You will receive an engine build with care second to none. We cover many applications from performance diesel to modern and classic performance gas engines. Every engine build is produced using a production style methodology. This approach helps us find problems before they leave the facility or get installed in a vehicle. This starts with intense organization, data collection, various checklist and a verification process to give us and you the confidence that your engine will perform just as advertised!

There are many different types of engines to be had by Centurion.

Below is a list of the most common:

New Production: These are engines that are manufactured with only new parts. All components have been carefully selected for consistency, quality, and availability. We develop our own “baseline” production specs and use this as the starting point for your custom build. As a general rule, these do not require any cores.

Remanufactured Production: This is very similar to the above with the exception that some components may be remanufactured. Generally, this consists of blocks, heads, crankshafts and some connecting rods. These engines require a core and depending on demand, should be in stock.

Non-Production New/Reman: These are engines that are either brand new components or some remanufactured that are not currently in an existing production line. The difference between these and the above is that generally these will take a bit more time to build, but there will be zero difference in the end product. Some of these will require core engines.

Competition Engines: These engines are different in their specific design for competition. These can be brand new or reman. Competition engines require a slightly different view point as we aren’t as concerned about the drivability and efficiency as we are with raw power at the right time, with the most reliability.

Every engine is serial numbered and has a “file” stored with all of the build and verification test information associated with it for life. We highly recommend oil analysis testing to be done by the customer even beyond the break-in process. We can supply these kits with instructions, and all of the data gets updated in our files for the life of the engine. This helps us help you keep track of wear patterns and trends. If there is a breakdown of a component or oil, we’ll see it before it becomes a big issue or even catastrophic. We can make recommendations to operating and maintenance procedures to make sure you get the most out of your engine. Buying an engine from Centurion is not a one time transaction, we remain partnered with you for the life of your new engine and into the next. It is our goal to build a life long relationship that is filled with satisfaction and performance!